AURORA PLASTICS BRANDS

AuroraFlex SL™

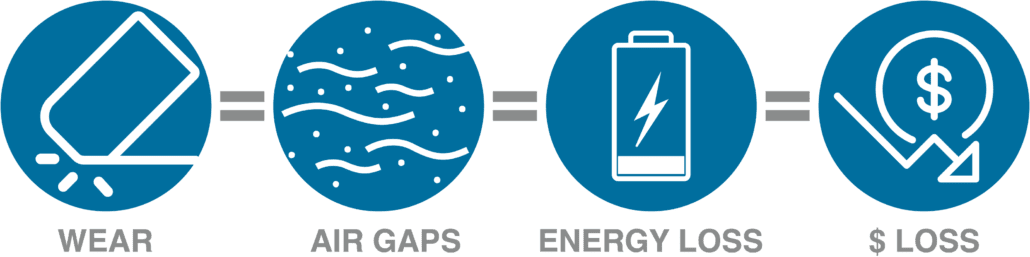

Aurora’s AuroraFlex SL products are ideal for door-bottom sweeps, refrigeration door gaskets, window gaskets and more. Standard PVC will wear over time, causing tearing. Tearing and overall wear creates a gap at the bottom of the threshold. Aurora’s solutions pass industry abrasion tests with no wear at all. Abrasion resistance is significantly improved with increased tensile and elongation properties. As a result, your customers will save energy and money.

Benefits of AuroraFlex SL in injection molding (TPE: Thermoplastic Elastomers/PVC) include faster injection molding cycles, lower colorant usage, brighter/better appearance, improved wear and abrasion resistance, resistance to soiling, improved hydrophobicity, easy assembly of interlocking features and energy damping properties.

Taber data taken from our TDS for G 3473SL shows that after 1000 cycles on the abrasion wheel, standard flex PVC of the same durometer had a weight loss of 7.5% as opposed to the AuroraFlex SL that only lost .4% weight.

AuroraFlex SL has 95% better wear resistance than standard flex PVC.

| % Loss / 1000 Cycles | % Loss / 1000 Cycles | ||

|---|---|---|---|

| Taber Abrasion (3473SL) | ASTM D4060 | 0.4 | 0.4 |

| Taber Abrasion (3473 Standard) | ASTM D4060 | 7.5 | 7.5 |