Electronics

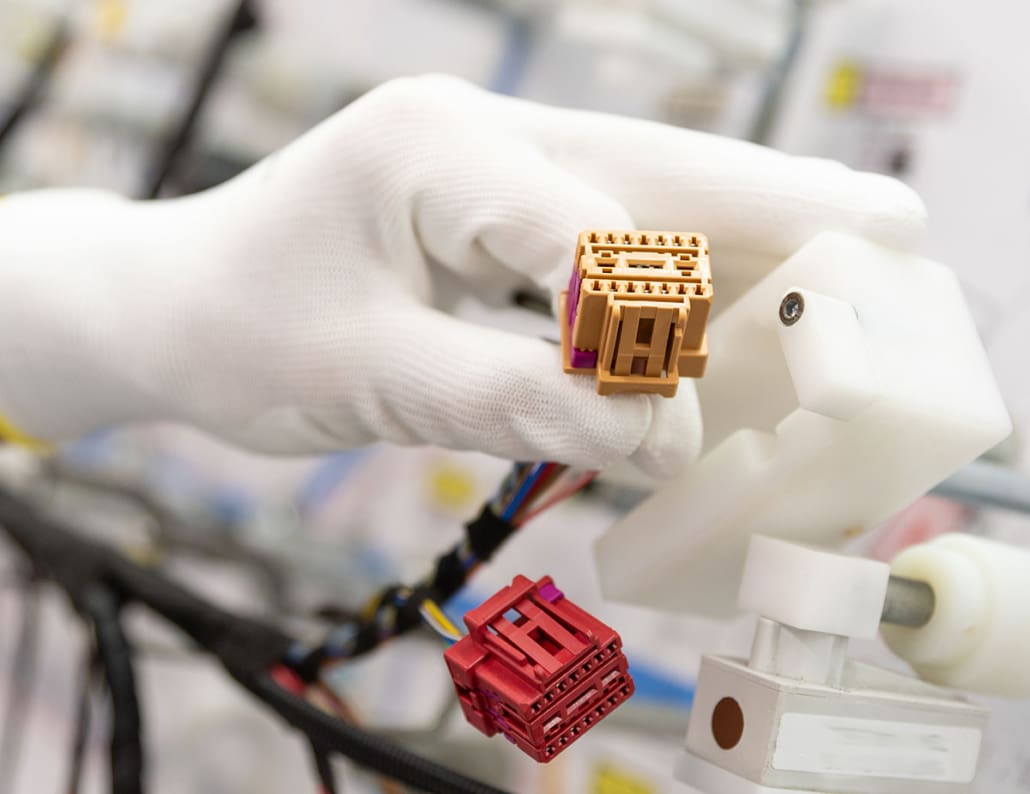

Aurora Material Solutions offers a wide range of compounds that deliver a variety of beneficial properties in electronics applications, such as flame retardancy, high strength, durability, heat resistance and electrical insulation.

These compounds include, PEI (polyetherimide), PC/ABS, PC/PBT, PC/PET alloys, PC (polycarbonate/polyethylene terephthalate) and PC (polycarbonate). These products can be glass filled and pre-colored as well.

Polymers in our AuroraGuard™ family are known for high-heat properties and durability in electronics applications.

- SBS and SEBS compounds utilize multiple TPE chemistries to impart high-performance properties for durability and easy processing. They range from clears to low gloss black glass reveals for roof ditch and under hood applications. There are hundreds of metallic body match color approvals, and all of these compounds are offered in both molding and extrusion grades.

- AuroraGuard ABS (acrylonitrile butadiene styrene) can be used for many decorative elements inside the car, including the glove box, threshold assembly and water tank mask. AuroraGuard ABS combines the strength and rigidity of the acrylonitrile and styrene polymers with the toughness of the polybutadiene rubber and is extremely heat resistant.

- Our AuroraGuard PBT (polybutylene terephthalate) is an engineering polymer that is thermoplastic, semi-crystalline and a type of polyester. PBT provides excellent chemical resistance, shrinks very little during forming, is mechanically strong, heat-resistant up to 150°C (or 200°C with glass-fiber reinforcement), and can be treated with flame retardants to make it noncombustible. It is often used in automotive applications, including bumpers, tailgate outer panels and door handles.

- AuroraGuard PC (polycarbonate) compounds are amorphous, thermoplastics that possess outstanding impact strength, excellent colorability, and superior heat resistance with good electrical and thermal properties, low- temperature toughness, and superior dimensional stability. They can be provided unfilled or filled with specialized fillers, mineral or fiberglass reinforcement. PC compounds are available in flame-retardant grades (both non-halogenated and brominated), a wide range of melt viscosities, and can be offered with recyclable PC content and ultraviolet (UV) stabilized grades for outdoor weatherable applications. The polycarbonate (PC) product family complies with FDA (Food and Drug Administration), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), NSF (National Sanitation Foundation) and UL listed (UL 94).

- AuroraGuard PEI (polyetherimide) compounds start from the base resin, amorphous polyetherimide, which is an amber-to-transparent thermoplastic with characteristics similar to the related, much more costly plastic PEEK. Our PEI compounds are inherently flame resistant and provide a high resistance to elevated temperatures and solvents. Compounds within the AuroraGuard™ PEI family provide high mechanical property performance in continuous use environments to 340°F (170°C). Their toughness and rigidity can be further enhanced with fiberglass reinforcement.

- AuroraGuard PC/ABS alloys provide impact strength, heat resistance, colorability, very good aesthetics and dimensional stability. These compounds are also available in a recyclable grade series, which are filled with specialized fillers, minerals, or glass. These grades exhibit a superb combination of thermal and mechanical properties, excellent impact strength, high heat resistance, dimensional stability, great processability, flame retardancy, and a wide range of viscosities.

Sign up for our Product Finder and gain access to our recent webinar.

AuroraFlex™ products offer thermoplastic elastomers based on SEBS and SBS polymers, high performance nitrile TPEs, TPOs and TPRs as well as flexible PVC compounds, with a variety of physical properties required for non-rigid applications. These include consumer and personal care products, housewares, tool and hardware, grips, lawn and garden, medical, electronics, automotive and non-automotive transportation, sports and leisure, marine, pool and spa, hoses, shoe soles, cove base molding and more.

AuroraFlex SBS and SEBS compounds utilize multiple TPE/TPR chemistries to impart high-performance properties for durability and easy processing. These materials have many of the same properties as vulcanized rubber, but can be molded and extruded using conventional thermoplastic process equipment. Thermoplastic processing provides advantages over vulcanized, thermoset rubbers, which are processed using a slower and more costly curing process. Most of our TPR formulations are 100% recyclable and are RoHS compliant.

As a cost-efficient alternative to our thermoplastic elastomers, we can provide AuroraFlex flexible PVC compounds that provide elastomeric performance. TPE options are available as low as 10A* up to 50D durometer hardness. Some of our TPEs are offered in clear, as well as oil free grades.

AuroraTec™ is Aurora Material Solutions’ line of weatherable and non-weatherable rigid PVC compounds.

- AuroraTec PC/PBT (polycarbonate/polybutylene terephthalate) compounds are alloys of amorphous polycarbonate and the semi-crystalline polybutylene terephthalate resin. These compounds offer good chemical resistance, great impact and heat resistance, as well as outstanding aesthetic and processability characteristics. Impact-modified grades can provide a high level of impact strength at low temperatures.

- AuroraTec PC/PET alloys combine the high-temperature resistance and dimensional stability of PC with the chemical resistance and durability of PET. They are commonly used in electronic enclosures and housings due to their high strength, toughness and impact resistance.

Our team will also work with you to complete the formulation, with fillers that offer more specific properties, like reduced shrinkage, increased weight, pigment, lubrication, biocides as well as UV- and chemical-resistance.