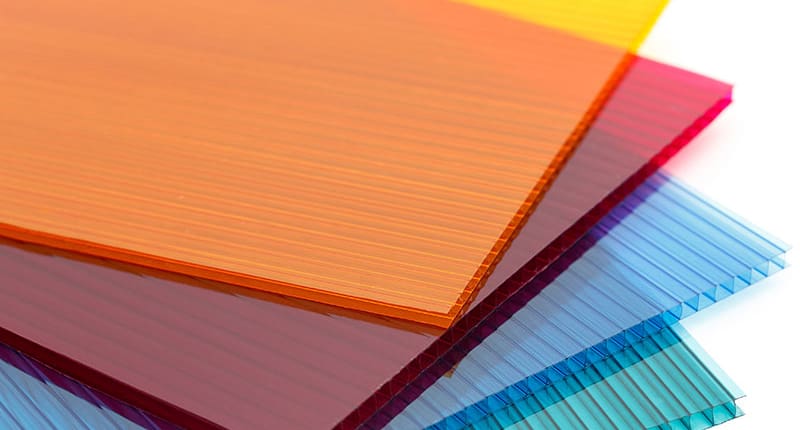

PC (polycarbonate)

Durable, high performing polycarbonates that help slow down the spread of fire.

When your project requires a proven flame-retardant polycarbonate, AuroraGuard™ has the solution. Our PC (polycarbonate) flame-retardant grades come in both non-halogenated and brominated compounds, assuring that harmful toxins aren’t released during a fire – adding an extra layer of safety.

Aurora Material Solutions’ PC (polycarbonate) compounds are amorphous, thermoplastics that possess outstanding impact strength, excellent colorability, and superior heat resistance with good electrical and thermal properties, low- temperature toughness, and superior dimensional stability. They can be provided unfilled or filled with specialized fillers, mineral or fiberglass reinforcement. PC compounds are available in flame-retardant grades (both non-halogenated and brominated), a wide range of melt viscosities, and can be offered with recyclable PC content and ultraviolet (UV) stabilized grades for outdoor weatherable applications.

The polycarbonate (PC) product family complies with FDA (Food and Drug Administration), REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), NSF (National Sanitation Foundation) and UL listed (UL 94).

Our PC compounds are part of the AuroraGuard™ family of products.

The AuroraGuard™ line of products includes a variety of high-performing compounds that are ideal for demanding applications. AuroraGuard compounds are known for their high-heat, low-smoke zero-halogen and flame-retardant properties and ability to be customized to each customer’s needs. We’ll provide the technical knowledge and support to bring your ideas to life. Our experienced R&D team will work with you to develop a formulation that will perform for your unique application goals – every step of the way.

Cutting Edge Polycarbonate Compound Solutions

Each new PC compound starts with a comprehensive review of your application. Contact us to engineer, test, manufacture and deliver a custom PC compound that exceed your expectations. You can trust an engineered thermoplastic compound to outperform comparable industry brands.

Our goal is to provide the highest quality products and the best customer service in the industry. We work closely with you throughout the process to meet your specific needs, from determining the formulation for the job, to assistance with colors and compound matching to working within your budget. You can trust us to deliver an engineered thermoplastic compound to outperform comparable industry brands, backed by the knowhow and service of Aurora Material Solutions.

We can work with you to develop custom sustainable materials that reduce manufacturing energy, produce less waste, and aid in water conservation.

PC Applications

Enter your information below to learn more about AuroraGuard™ PC (polycarbonate).

"*" indicates required fields