AuroraGuard™ CPVC Compounds

Bring the benefits of CPVC to more applications.

You know and trust AuroraGuard™ for its high-heat, low-smoke, zero-halogen and flame-retardant properties. Now we’re bringing the performance of CPVC to the AuroraGuard™ line for even better flame retardancy, low shrinkage at higher temperatures, lower smoke density – and more.

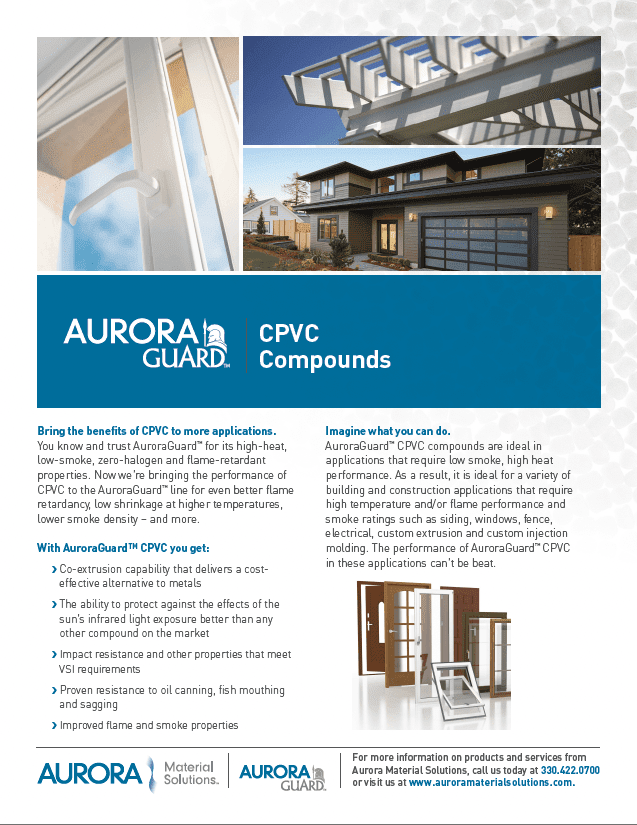

AuroraGuard™ CPVC Compounds are ideal in applications that require low smoke, high-heat performance. As a result, it is ideal for a variety of building and construction applications that require high temperature and/or flame performance and smoke ratings such as siding, windows, fences, electrical, custom extrusion, and custom injection molding.

With AuroraGuard™ CPVC you get:

- Co-extrusion capability that delivers a cost- effective alternative to metals

- The ability to protect against the effects of the sun’s infrared light exposure better than any other compound on the market

- Impact resistance and other properties that meet VSI requirements

- Proven resistance to oil canning, fish mouthing and sagging

- Improved flame and smoke properties

Dark colors? Weather exposure? No problem.

Whether your application includes dark siding colors or other exterior features, AuroraGuard CPVC compounds are designed not to warp, even under the elevated temperatures caused by the sun’s infrared light. CPVC is proven to deliver incredible dimensional stability up to 212°F (100°C) – creating extreme protection against the sun’s infrared light, season after season, even in high altitude applications. Plus, AuroraGuard™ CPVC can be coextruded with AuroraShield™ capstock for enhanced UV and water-whitening resistance. Our experts will work with you to create the right formulation, considering all factors that meet your specific application needs.

Enter your information below to learn more about AuroraGuard™ CPVC Compounds.

Enter your information below to learn more about AuroraGuard™ CPVC Compounds.

"*" indicates required fields

Enter your information below to learn more about AuroraGuard™ CPVC Compounds.

Enter your information below to learn more about AuroraGuard™ CPVC Compounds.