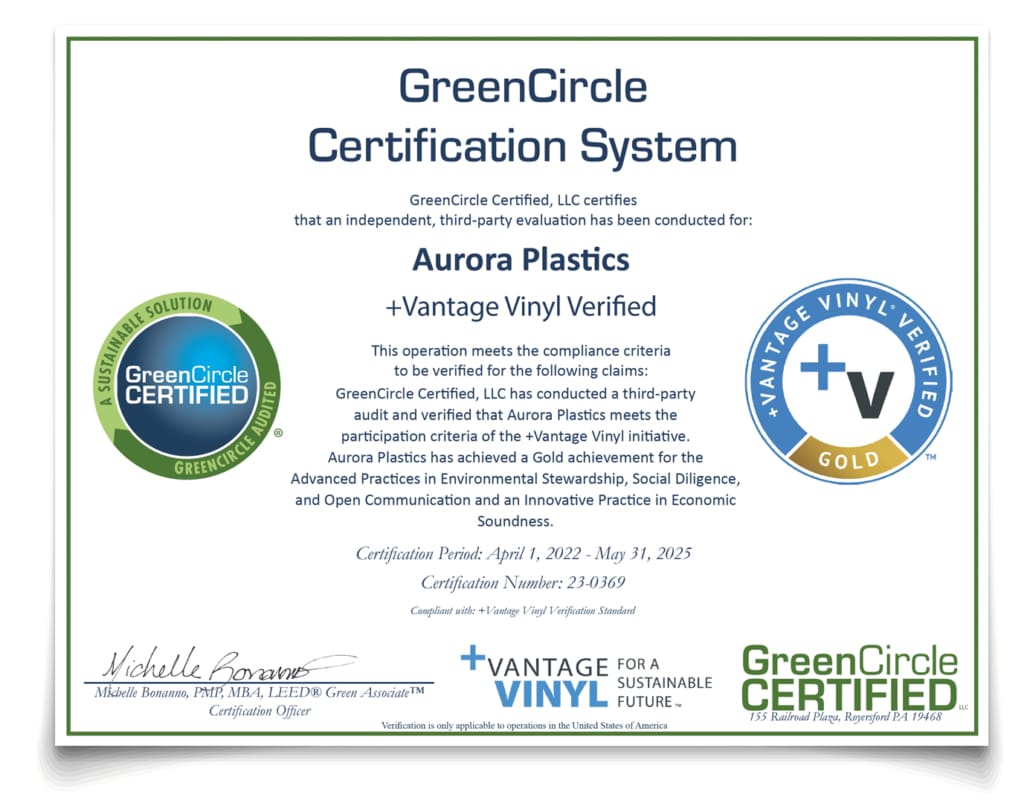

Our Commitment to Sustainability

Aurora Material Solutions is committed to being a sustainable and responsible leader in the industry by continuously seeking ways for its manufacturing operations to have the smallest possible environmental impact.

Our goal is to enhance the quality of life for our employees, customers and the communities in which we operate, and that goal guides the company’s day-to-day operations.

Aurora Material Solutions maintains six manufacturing facilities in both the U.S and Canada. The company has integrated pollution prevention, biodiversity, and resource conservation into business decision making. Aurora Material Solutions is continuously seeking to develop and improve operations and technologies to decrease waste, prevent pollution, and minimize health and safety risks.