Flexible PVC provides unmatched durability in the harshest conditions

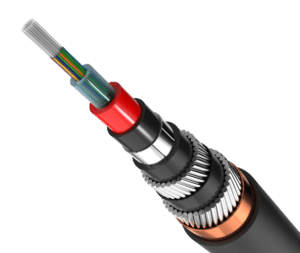

AuroraGuard™ flexible PVC compounds provide high-heat, low-smoke, zero-halogen and flame-retardant properties. Low-Smoke zero-halogen (LSZH or LSOH) is a type of plastic used in the wire and cable industry for cable jacketing. LSOH cable jacketing is custom compounded to produce minimal smoke and low toxicity when exposed to fire.

Most network cables (CAT5, CAT6, etc.) are insulated with polyvinyl chloride (PVC), polyethylene, or thermoplastic urethane (TPU). In a fire, halogen-containing plastic releases hydrogen chloride, a poisonous gas that forms hydrochloric acid when it comes in contact with water. Low-smoke zero-halogen cables do not produce this toxic combination of gas, acid and smoke when exposed to flame.

Since harmful toxins are minimized, LSOH/LSZH material is usually used in poorly ventilated areas such as plenum, aircraft, rail cars, and tunnels, in which smoke is likely to both build up and come into contact with people. Low-smoke zero-halogen material is becoming very popular and can be required when the safety of people and equipment is critical. Low-smoke zero-halogen compound also has the added benefit of complying with the European Union’s Restriction of Hazardous Substances (RoHS) directive and similar North American safety and environmental standards.

AuroraGuard PVC provides the perfect blend of flexibility and strength

Our innovative line of LSOH/LSZH compounds falls into two families:

- EXTRUSION GRADES – By using special grades of metal hydroxide and very unique resin combinations, we develop a series of one of the most flexible zero halogen compounds on the market, having a -50°C to 90°C+ continuous use temperature rating, as well as exceptional physical and processing characteristics.

- MOLDING GRADES – Using advanced phosphorusnitrogen chemistry, Aurora Material Solutions developed a high grade FR intumescent compound with UL 94 VO rating down to 40-45 mils. Other special characteristics of these compounds are good thermostability and low moisture sensitivity.

The goal of concentrates is the ideal dispersion of additives in the polymer matrix. The fine, powdery feed material often tends to agglomerate and therefore is difficult to work with. Concentrates (masterbatches) with an additive share of 20 – 90% are available, depending on the feed material.

Enter your information below to learn more about AuroraGuard™ Flexible PVC.

"*" indicates required fields